Laser Scanner 3D

3D reality capture solution

Ground and structure topographic survey

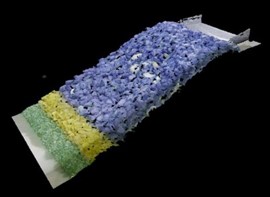

The Leica RTC360 3D Scanner is used to characterize and monitor the evolution of structures tested in the laboratory. It is used for the quality control of the modeled topo-bathymetry construction. It also makes it possible to follow changes in the shape of structures (reprofiling) during the testing process. For morphodynamic models, it measures the bathymetry evolution. Thus, 3D scanning is a polyvalent tool supporting the physical modeling of your projects, from construction to appraisal of test results.

The laser scanner makes it possible to capture the evolution of the model in 3D, immediately after our tests. With a measurement rate of up to 2 million points per second and an advanced wide-range imaging system, the creation of colorful 3D point clouds can be achieved in less than 2 minutes.

Low-interference data results in better images, resulting in crisp, high-quality scans that are rich in detail and can be used to represent the condition of the structures under test. Combined with the Cyclone software suite for automated field recording, the Leica RTC360 offers exceptional accuracy that is immediately visible and verifiable.

Analysis of damage to rubble-mound breakwater

3D scan of the model’s armour before and after testing to quantify displacements of rocks or concrete units following exposure to the series of waves.

- Digital post-processing of the topographic survey with Register 360 software for georeferencing the recorded point cloud

-

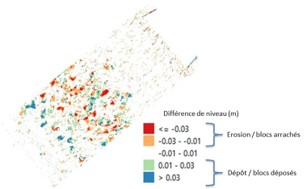

For rock armour slope protection, the Digital Terrain Model (DTM) can be processed using a Geographic Information System such as QGIS. Comparing DTMs of the armour throughout the series of tests makes it possible to quantify shell deformation and damage progression.

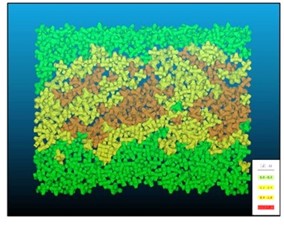

- For armour made of artificial concrete blocks, the georeferenced point cloud is analyzed by shape detection using the patented SEABIM® process. The software creates a digital twin of the modeled shell, enabling each block to be individually identified on the scan output. By comparing the different surveys, the displacements of each armour unit can be identified and quantified.